How does a lithium battery "starve to death" activate?

How long do lithium batteries last? What is the life of lithium batteries?

48V lithium battery, 48V lithium battery how much?

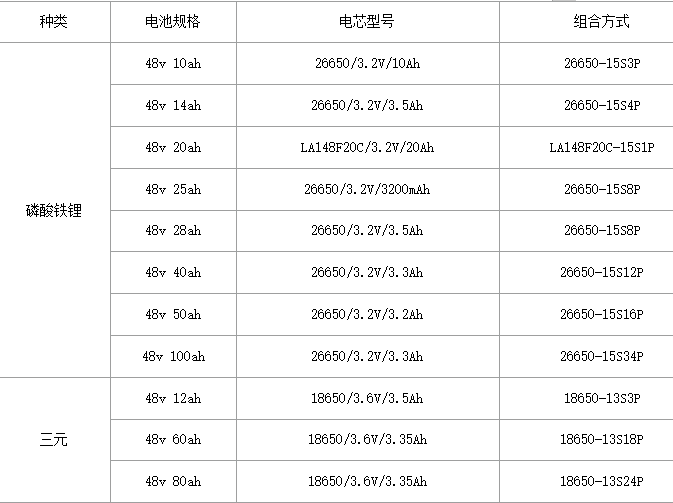

48V lithium ion battery pack model table

48V lithium ion battery charger

48V lithium ion battery charger is specially used to charge the nominal voltage of 48V lithium battery charger. Lithium batteries have high requirements for chargers and need to protect the circuit, so lithium battery chargers usually have high control precision and can charge the lithium batteries at constant current and constant voltage.

The lithium battery charger has the function of overvoltage protection and temperature protection. The lithium battery charger is connected with the external current-limiting charging power supply and p-channel field effect tube, which can charge a single lithium battery safely and effectively. Its biggest characteristic is that it can achieve very low power dissipation without using inductance, and adopts 8-pin μMAX package. The charging control accuracy is 0.75%, which can realize pre-charging. The maximum charging time limit provides secondary protection for lithium battery. The floating charging mode of lithium battery charger can maximize the battery capacity.

47.5V 4A lithium iron phosphate battery charger

Input voltage: 100-240V,50-60Hz

Output voltage: 47.5V

Output current: 4A

Application: 13 41V lithium iron phosphate battery packs

Product size: 178*80*46mm

Product weight: 0.8kg/ PCS

Safety standard: UL1012 IEC60335 IEC61558

Certified: UL, cUL, GS, CE, ROHS, REACH, SAA, PSE, CCC

Features: with reverse connection/overload/overcurrent/short circuit/high temperature automatic protection function, parallel rail charging, automatically capture and track battery voltage, lock charging current, temperature rise sensing, step-down stay, color changing light-emitting diode display full charging status

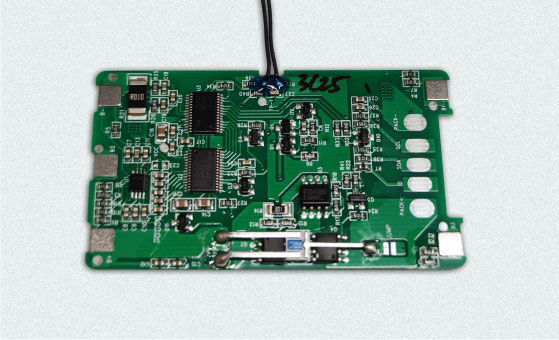

48V lithium ion battery protection plate

48V lithium ion battery protection plate, namely the protective role of the circuit board. It is mainly composed of electronic circuits, which can accurately monitor the voltage of the cell and the current of the charging and discharging circuit at the temperature of -40℃ to +85℃, and timely control the on-off of the current circuit.

The lithium battery protection plate can protect the charge and discharge of the series and parallel battery pack, and detect the state of over voltage, over current, over temperature, under voltage and short circuit of each single battery in the battery pack, prolong the service life of the battery, and avoid the damage of the battery due to over discharge. Lithium battery protection plate is an indispensable part of lithium battery.

48V lithium ion battery BMS

48 v lithium-ion battery management system (BMS), through to detect the state of each monomer battery of lithium battery to determine the status of the battery system, and according to their status to lithium battery system adjustment and the corresponding control strategy implementation, implementation of lithium battery system and to ensure that the lithium battery charge and discharge of each monomer management system safe and steady operation.

48V lithium ion battery BMS features

The lithium ion battery management system consists of a management host (CPU), a voltage and temperature collection module, a current collection module and a communication interface module.

It can detect and display the total voltage, total current and reserve power of lithium ion battery pack; The voltage of any single cell and the temperature of the cell box; Maximum and minimum battery voltages, battery numbers, maximum and minimum temperatures, and charge and discharge quantities of battery strings.

4 Lithium ion battery host also provides alarm and control output interface, alarm and control output for overvoltage, undervoltage, high temperature, low temperature, overcurrent, short circuit and other extreme situations.

Provide RS232 and CAN bus interface, CAN directly read all information on the lithium battery management system on the computer.

Note for use of 48V lithium ion battery

If lithium ion batteries are stored for a long time, they should be kept in 50%-60% full charge state. They should be replenished once every three months and charged and discharged once every six months.

In the transportation process, pay attention to moisture and moisture, avoid extrusion, collision, etc., to avoid damage to the lithium ion battery.

Do not use or place lithium-ion batteries at high temperature (under hot sun or in a hot car). Otherwise, the batteries may overheat, catch fire, fail to function and shorten their service life.

Do not store in a place with strong static electricity or magnetic field. Otherwise, the battery safety protection device may be damaged, resulting in unsafe risks.

If the lithium-ion battery gives out peculiar smell, heat, discoloration, deformation or any abnormality occurs during use, storage or charging, remove the battery from the device or charger immediately and stop using it.

48V lithium ion battery vs. lead acid battery

Weight energy density

At present, the energy density of lithium battery is generally 200~ 260Wh/g, and the lea

48V lithium ion battery

1, 48V lithium ion battery charging matters needing attention

Charge strictly according to standard time and procedure.

Lithium battery factory is generally charged half state, the first use must be fully charged battery.

Use the original charger, the original charger supporting strong performance, moderate charging rate.

Do not always charge until the undervoltage protection circuit is active. The concept of recharging after completely discharging the electricity is not correct, the greater the discharge depth, the more times of use of deficient electricity, the shorter the service life of lithium battery.

2. How many kilometers does the 48V lithium ion battery run with full electric energy?

The battery life of 48V lithium ion battery is related to the capacity of the battery itself (Ah) and the motor power of the electric vehicle (W). Now the electric bicycle on the market in line with national standards generally uses 48V 12Ah lithium battery and 350W motor. With the development of battery technology, their theoretical endurance can reach 50km. The actual range depends on the weight of the passenger and the weight of the vehicle.

How many kilometers can a 48-V lithium-ion battery run on full electric energy depends on battery capacity, motor power and load capacity. Generally speaking, 48V 12Ah, 350W lithium battery can run 50km. 48V 20Ah can run 70km. The 72V 22Ah lithium battery has a range of 90 kilometers.

3. How many hours does it take to charge the 48V lithium battery?

Charging time doesn't have much to do with voltage;

Basically see the capacity of lithium ion battery and the power of the charger, charging time = lithium battery capacity ÷ charging current

For example, 48V 20Ah lithium ion battery uses a regular 48V 2A charger, so the theoretical charging time is 2 hours, that is, 20Ah÷10A=2h, but the actual charging constant flow constant voltage mode, in the last stream charging time is long, so under normal circumstances are about 3 hours. Similarly, the 48V 5A charger needs 20Ah÷5A=4h, but it also has trickle time, so it is about 5 hours.

4. How to do if the 48V lithium ion battery cannot be charged?

Charger output parameters are normal, voltage, current, etc.;

Whether the charger line is normal, whether the connection is broken;

Lithium battery is broken, you can test the battery open circuit voltage is normal;

? Consult lithium battery manufacturers.

5, 48V13 string and 14 string difference

Ternary is 13 or 14 strings, lithium iron phosphate is 16 strings

But ternary 13 series discharge platform is obviously lower than 48V, the speed is slow, 14 series is good

13 series full voltage 13*4.2=54.6V, rated voltage 13*3.7=48.1V, cut-off voltage 13*3.2 = 41.6V

Full voltage 14*4.2=58.8V, rated voltage 14*3.7=51.8V, cut-off voltage 14*3.2 = 44.8V

13 series can be better compatible with lead acid battery electric vehicle, lead acid battery electric vehicle normal is 12*4= 48V, up to the voltage 10.5*4 =42V

In addition, 48V 13 series and 48V 14 series charger voltage is not the same, can not be universal, some chargers can adjust the voltage can be universal.

How to improve the energy density of lithium battery?

What is the system energy density?